Researchers have made a significant breakthrough in understanding fusion processes by developing a novel X-ray imaging technique. This advancement is crucial for creating clean energy alternatives by replicating the sun’s fusion reactions in the lab.

The focus is on inertial fusion energy experiments, which require precise configurations of fusion fuel. A promising approach involves using porous nanofoams. However, previous methods either damaged these materials or lacked the resolution needed for detailed study.

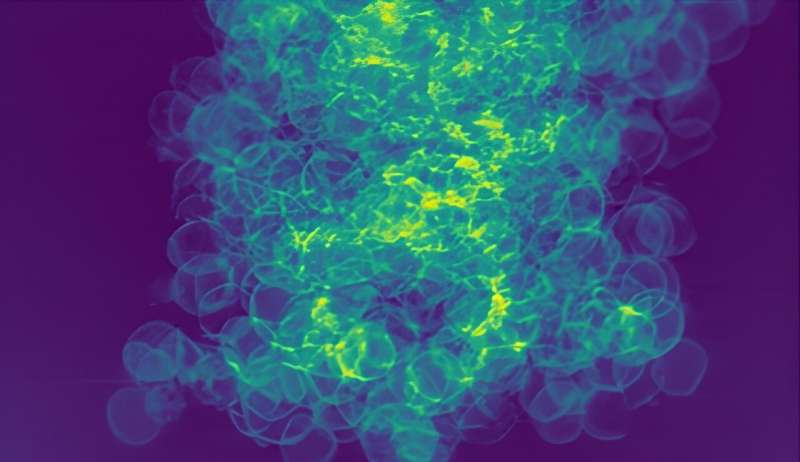

Recently, scientists have introduced an innovative X-ray imaging method utilizing the unique capabilities of the Linac Coherent Light Source (LCLS) at the Department of Energy's SLAC National Accelerator Laboratory. This technique has achieved unprecedented precision in resolving the 3D nanostructure of a copper foam, essential for fusion experiments.

This ptychographic imaging method generates detailed images by analyzing photon patterns scattered off the sample. Researchers used LCLS's X-ray free-electron laser to scatter photons from copper foam samples and then employed computer algorithms to reconstruct the original foam structure with nanoscale resolution. By rotating the samples, they were able to create a 3D image.

The findings revealed that the copper foam was less uniform than expected. Many foam layers were distorted or merged, which could influence their effectiveness in inertial confinement fusion experiments. This insight could help refine foam fabrication techniques and tailor these materials for better performance in fusion studies.

This study was a collaborative effort involving material experts from Lawrence Livermore National Laboratory, coherent imaging specialists from Los Alamos and Brigham Young University, and experimental designers from SLAC.

The researchers believe their technique could pave the way for future imaging experiments. They plan to apply this method to other fusion-related materials and potentially to other nanoscale structures or delicate samples. This approach might also integrate additional sensors to track 3D nanostructures over time or map chemical distributions.

:max_bytes(150000):strip_icc():format(webp)/alec-baldwin-torino-film-festival-121824-3cf7cfbe5c4f4bcbb9197de4de062ea6.jpg?strip=all&resize=370,370)

:max_bytes(150000):strip_icc():format(webp)/Jimmy-Fallon-and-Prince-Harry-092624-baa1362d743d4f39a7d60bf57eb6e8b2.jpg?strip=all&resize=370,370)

:max_bytes(150000):strip_icc():format(webp)/randy-moss-121324-40b858c71b0f40bfa399e2fe00152b2a.jpg?strip=all&resize=370,370)

:max_bytes(150000):strip_icc():format(webp)/scandal-kerry-washington-121824-c51a2b5f0ef741268474bec2498c285a.jpg?strip=all&resize=370,370)